ESG management in Supply Chain

ESG management in Supply Chain

■ Roles and Responsibilities of Supply Chain Management

The ESG Committee under the Board of Directors of Pulmuone held twice a year to discuss: 1. the Company's supply chain management strategy; 2. the Company's supply chain management mid-term and long-term goals; and 3. other supply chain management matters deemed necessary by the Board of Directors and its committees. The roles and responsibilities of the ESG Committee are to identify various topics and issues related to ESG management, including the company's supply chain management, to review the company's ESG strategy and targets, and to continuously evaluate and review the performance. In 2022, the supply chain ESG assessment performance and plan was reported to the ESG Committee. The roles and responsibilities of the ESG Committee under the Board of Directors and its subcommittees are stipulated in Article 2 and Article 10 of the ESG Committee Operating Regulations.

■ Pulmuone Purchase Policy

The Purchase Policy applies to all direct and indirect purchases of goods and services by the employees of Pulmuone and all its business units (subsidiaries). It states rules on purchase practices such as the prohibition of unfair acts and bribery and security of supplier information (Chapter 5), matters related to the management and support of suppliers including performance evaluation (Chapter 8), and definitions and management processes for types of risks and other ESG factors such as compliance, human rights, ethics, and environment (Chapter 9). Code of conduct review is included in the procurement and contracting requirements, and we continuously monitor and update its compliance with supply chain ESG requirements.

■ Code of Conduct for Suppliers

Pulmuone established a Code of Conduct for Suppliers to help our suppliers fulfill their corporate social responsibility and ensure that suppliers agree to comply with it while doing business with us. The Code of Conduct for Suppliers specifies Pulmuone’s requirement for our suppliers to build a safe working environment, respect the human rights of their employees, and fulfill their environmental obligations, while conducting their management activities in an ethical manner. Pulmuone amends the Code of Conduct through ongoing communication with suppliers and visits the supplier's operations to conduct due diligence to make sure they abide by the code.

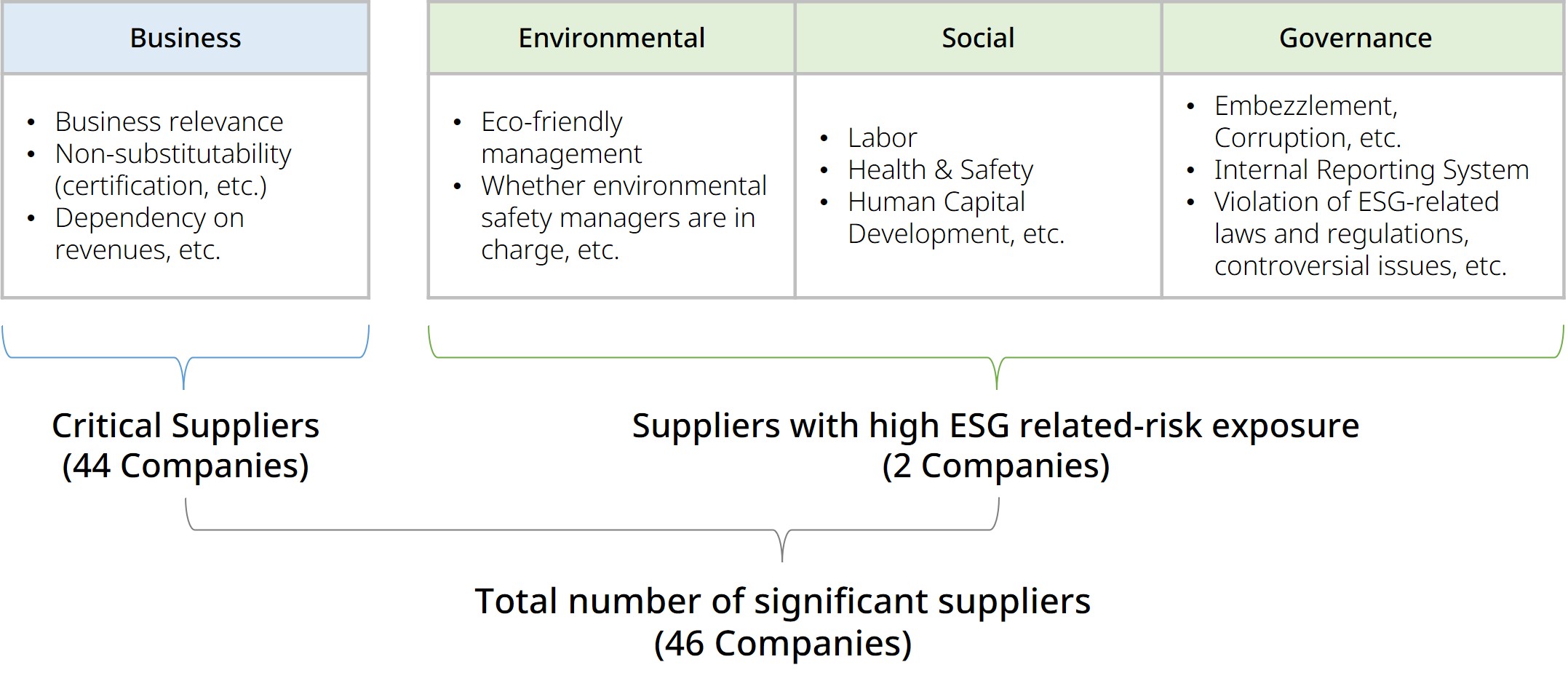

■ Supplier Screening & Identifying Significant Suppliers

Pulmuone's Significant Suppliers are defined as Critical Suppliers based on business aspects and Suppliers with High ESG Risk Exposure based on ESG aspects. Critical suppliers are selected by screening all suppliers annually based on business aspects (business relavance, non-substitutability, dependency on revenue, etc.). In addition, suppliers with high ESG risk exposure are identified through new supplier screening and regular supplier evaluations that include ESG-related questions such as labor, safety, environmental management, and compliance. These screenings and evaluations are divided into the areas of original equipment manufacturers (OEMs), packaging materials, and raw materials, with different evaluation factors depending on the purchase items and business characteristics.

[Aspects of Supplier Screening]

[Supplier ESG Assessment Process]

[Supplier Screening]

■ Supply Chain ESG Assessment Process

In order to determine the level of ESG management in the supply chain and to identify and manage risks, Pulmuone has established and operates a supply chain ESG assessment system. The supply chain ESG assessment was developed based on initiatives such as the Responsible Business Alliance (RBA) and Ecovadis, as well as the specifics of the food industry. To enhance the effectiveness of the supply chain ESG assessment, we provide training on ESG management and guidance on supply chain ESG assessment before conducting the self-assessment.

Through the online supplier ESG self-assessment system, each supplier submits responses and supporting documentation. The suppliers' potential ESG risks identified through the self-assessments are further verified and validated through an on-site inspection process conducted by a specialized external organization. The results of the assessment are shared with suppliers to enable them to develop and implement improvements on their own, and we plan to offer a one-point ESG consulting training program.

Also, we conduct annual audits of all suppliers who supply finished products to Pulmuone. The audits are conducted according to the evaluation criteria of the Pulmuone's Food Safety Management System. The evaluation indicators are evaluated for violations of ESG-related laws and regulations and social issues. The evaluation results are reflected in the regular supplier evaluation. We support the establishment of improvement plans for corrective and preventive actions. Each supplier submits a corrective action plan to Pulmuone's procurement portal, and Pulmuone monitors that the action is properly implemented and completed. As a result of the audit, companies that are found to be non-compliant are given a period of time to improve. If there is no improvement after the first and second re-inspection, we terminate the transactions.

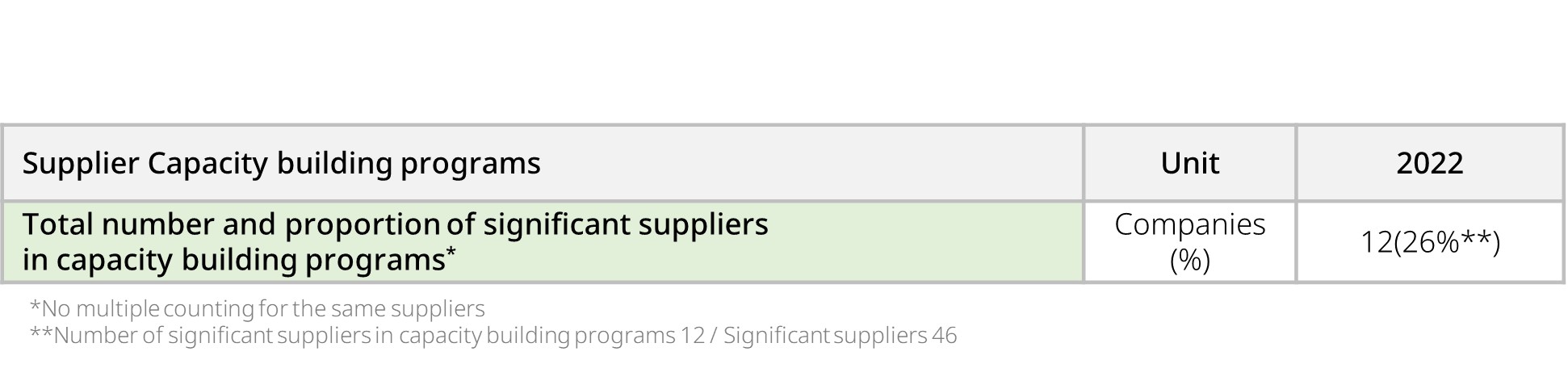

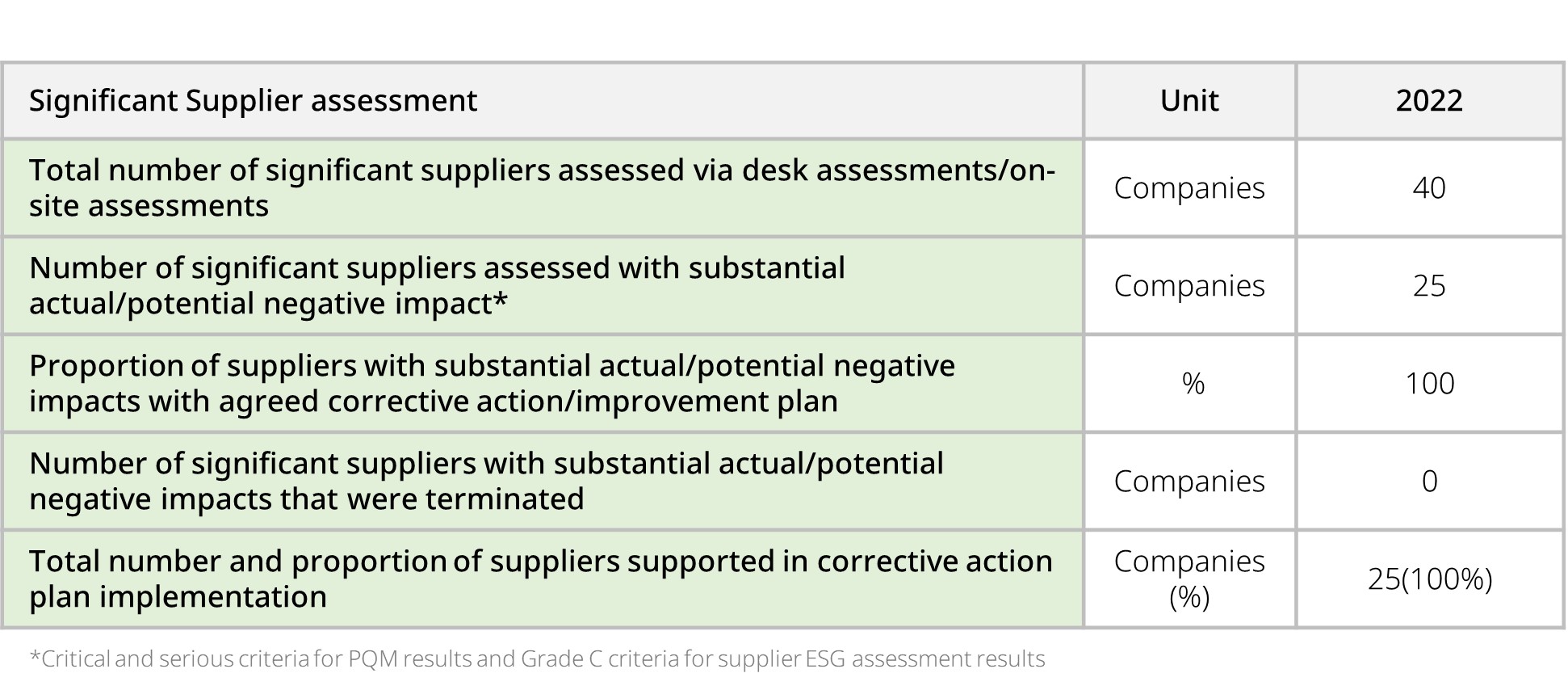

[Significant Supplier assessment]

■ Support for strengthening supply chain ESG capabilities

Establishment of a digital cluster smart factory :

Since 2021, we have invested a total of KRW 4.7 billion (including KRW 2 billion in government support) to build a system that enables data sharing and integrated management of manufacturing, production, and quality by utilizing the 4th industrial revolution technologies such as IoT (Internet of Things) and big data at six partner companies that manufacture frozen food, tofu, and kimchi. This is the first digital cluster smart factory in Korea that enables efficient management of information directly related to food safety such as manufacturing, production, quality, and delivery by linking the systems of partner companies with the systems of our eight factories. Based on this digital system, suppliers have been able to obtain Smart HACCP certification, further strengthening their food safety management.

Support for ESG Diagnosis and Education :

In 2022, we conducted ESG assessment for 24 suppliers and identified major improvement issues. We shared these with each supplier to support improvement and capacity building, and provided ESG and environmental education to improve their understanding of ESG management.

[Targets and Achievements for 2022]